The next generation high efficiency chiller product with high COP and IPLV carried out the dynamic gas bearing centrifugal compressor. The compressor reaches the take-off speed from zero, and the rotating shaft enters the suspension state. The start-up phase is similar to a rolling friction take-off of an aircraft.

BOLANG factory hold professional training session for high efficiency chillers for foreign trade technical sales team. From the basic structure and principle of the detailed explanation, gradually to the function of the product application, as well as the green energy-saving characteristics of the case study.

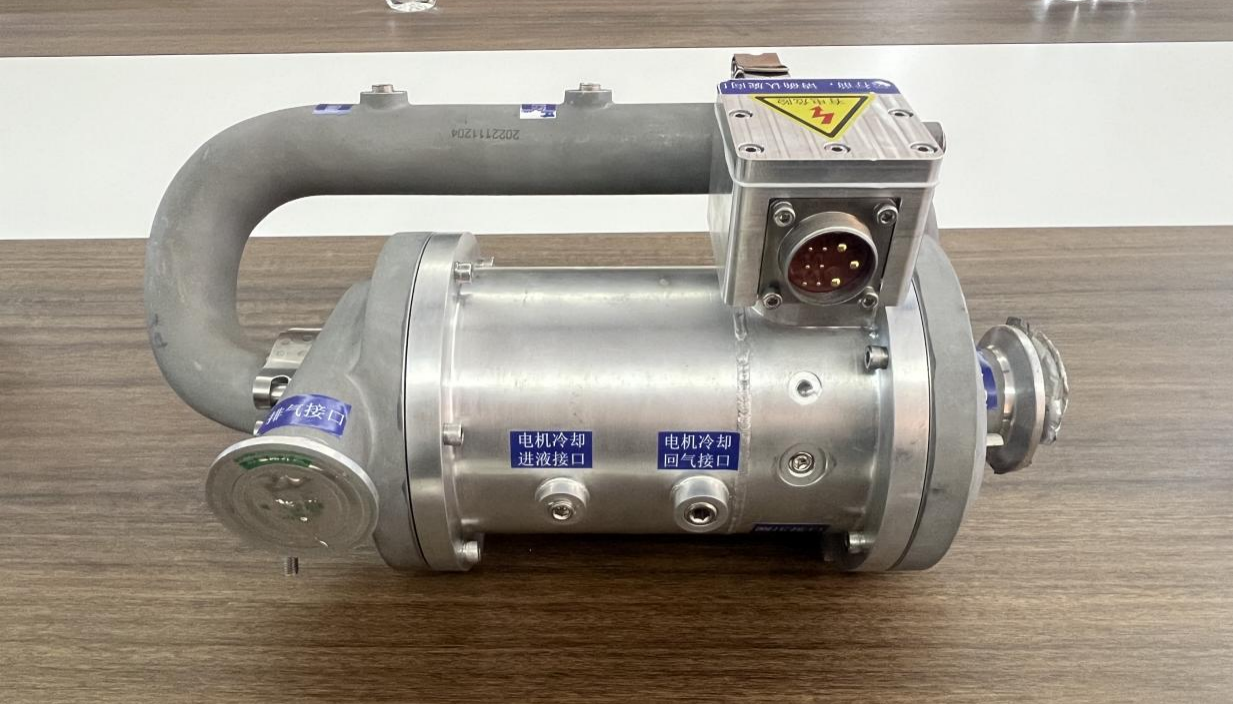

The training was aimed at explaining the appearance of the product, as well as the role of the core components and materials were analyzed, making it easier to understand the high efficiency chiller product.

There are three main merits for this chiller product:

1.Lubricating oil free. Dynamic pressure cyclone floating bearing, no lubricating oil system, no need to start before preparation, can be continuously started and stopped.

2.High efficiency. Wide operating conditions aerodynamic performance design, efficient permanent magnet motor matching, bearing no additional power, no additional gas supply. Extremely high COP/IPLV energy efficiency.

3.Durable and reliable. The compressor can be started and stopped up to 250,000 times.

After listening, the participants said, "After attending this training session, it has not only strengthened the knowledge base, but also broadened their horizons."

The training enabled the company's front-line management and technical and sales staff to have a more updated understanding of the basic structure and principles of the new compressor.

Post time: Dec-02-2023

BLG.png)