High-Quality Ice Block Making Machine from Leading China Manufacturer

As a B2B purchaser searching for a reliable ice block making machine, you’ll appreciate the efficiency and quality I can offer. Our machines, manufactured in China, are designed to meet high production demands, ensuring seamless operations for your business. With advanced technology, these machines produce crystal-clear ice blocks quickly, helping you to maintain your business’s competitiveness. I understand the importance of durability and reliability in your operations, and our machines are built to last, minimizing downtime. The intuitive design makes them easy to operate, allowing your staff to focus on other important tasks. Plus, our commitment to excellent customer service means that I’m always here to help with any questions or technical support you might need. Choosing the right manufacturer is crucial for your investment, and I assure you, our proven track record speaks for itself. Let’s boost your production and customer satisfaction together!

Ice Block Making Machine Factory Where Innovation Meets 2025

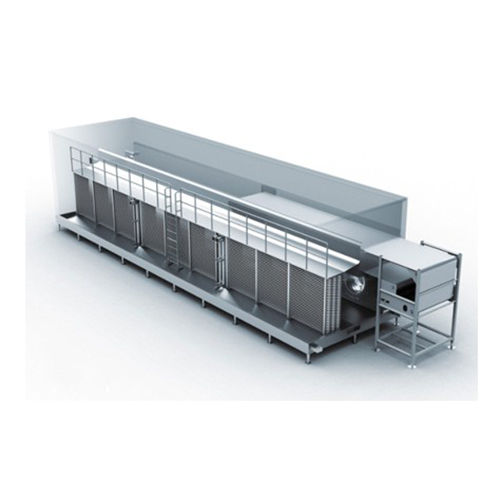

In the ever-evolving world of manufacturing, the demand for innovative solutions is higher than ever. At the forefront of this evolution is the ice block making machine industry, where cutting-edge technology intertwines with efficiency to meet global needs. As we approach 2025, businesses are rethinking their production processes, emphasizing sustainability and superior quality. The use of advanced materials and automation tools in ice block machines not only enhances output but also reduces energy consumption, making them an ideal choice for eco-conscious enterprises. Manufacturers worldwide are increasingly seeking reliable partners equipped with the latest technology to optimize their operations. Modern ice block making machines offer features such as programmable control systems, faster freezing cycles, and better insulation techniques, ensuring high-quality ice at a lower cost. This innovation drives down overhead while maintaining the standards required in various sectors, from hospitality to food preservation. Global buyers should prioritize suppliers that align with their sustainability goals, as the need for efficient resource management becomes crucial in today’s market. Investing in state-of-the-art ice block making machines could be the decisive factor for companies looking to enhance their competitiveness in a crowded landscape. By collaborating with a forward-thinking manufacturer, buyers can leverage not only advanced technological solutions but also valuable industry insights that can propel their business into the future. As we look towards 2025, the focus will surely remain on those who dare to innovate and adapt in this dynamic environment, ensuring long-term growth and sustainability for all.

Ice Block Making Machine Factory Where Innovation Meets 2025

| Feature | Specification | Application | Energy Efficiency |

|---|---|---|---|

| Production Capacity | 5000 kg/day | Food Industry | 95% Efficiency |

| Cooling Method | Direct Expansion | Restaurants | Low Power Consumption |

| Controller Type | PLC | Aquariums | Smart Energy Management |

| Safety Features | Emergency Stop, Overload Protection | Events and Parties | Compliant with Safety Standards |

| Dimensions | 2m x 1.5m x 1.2m | Supermarkets | Compact Design |

Related Products

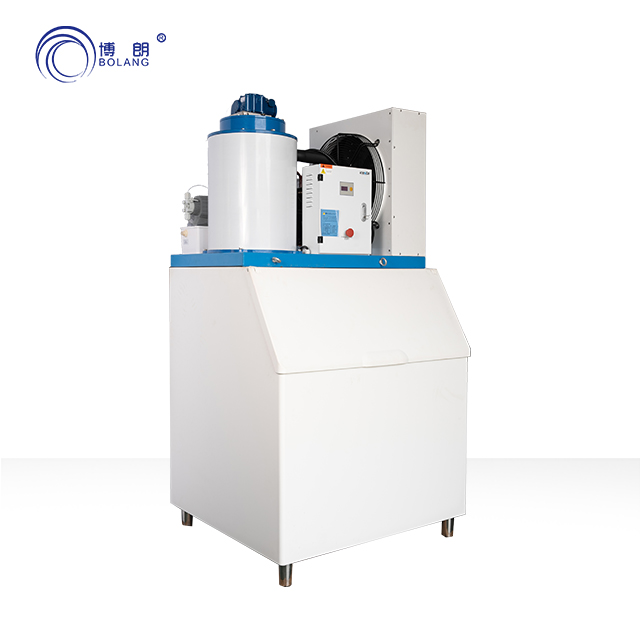

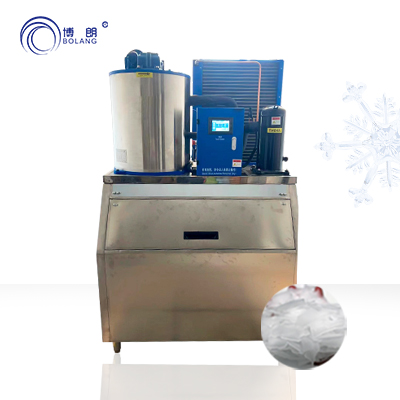

Ice Block Making Machine Supplier Factory

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

-

skype

Judy

-

Top

BLG.png)

1.jpg)

.jpg)

.jpg)