Cold Storage Project

Overview

Features

1. The cold storage project will be using Bolang's self-designed and produced refrigeration units, ensuring optimal system matching. The units have an optimized energy regulation control strategy and a reliable winter operation mode. The unit can automatically match the load changes and adjust the number of compressors startups, which is convenient and energy-saving. Winter operation mode is achieved by providing a control method for cooling water pump frequency conversion and fan frequency conversion during winter startup, winter operation, and transitional periods.

2. The air cooler is designed specifically for refrigeration, freezing, and preservation to extend the storage period of products and maximize product quality assurance. The coil undergoes an air tightness test at 2.8 MPa pressure to ensure high air tightness quality characteristics upon leaving the factory.

3. Cold storage board is an insulated panel designed to keep the thermal insulation for the cold room. Cold storage boards are made of different types of insulation materials and can vary in thickness and size. The material used to make cold storage boards varies depending on the specific application and requirements. However, some common materials used for insulation in cold storage boards include: 1. Polyurethane foam (PU) 2. Extruded polystyrene foam (XPS)3. Expanded polystyrene foam (EPS) etc.

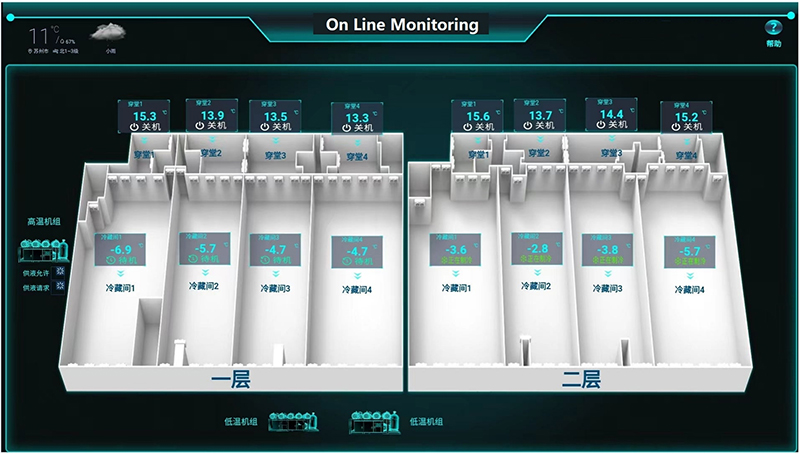

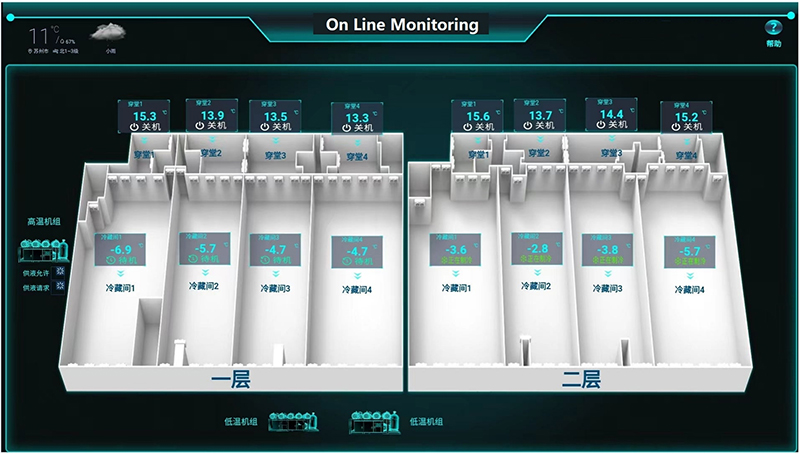

4. Online monitoring systems for cold storage can provide an efficient and convenient way to manage and track the temperature and humidity levels within a cold storage facility. One of the main benefits of utilizing such a system is the ability to identify and respond to potential issues before they result in any damage to the stored goods. For instance, if the temperature in the storage area rises above a certain threshold, the server sends an alert that can be addressed promptly.

Parameters

| Items | Cold Storage Project |

| Serial code | BL-, BM-() |

| Cooling capacity | 45 ~ 1850 kW |

| Compressor brand | Bitzer, Hanbell, Fusheng, RefComp and Frascold |

| Evaporating Temp. range | -85 ~ 15 |

| Application fields | Cold storage, Food processing, pharmaceuticals, Chemical industry, distribution center… |

Application

Meat Frozen Storage

Fruit and Vegetables

Inner Mongolia organic pigment material quick-frozen storage

Thailand durian fruit pulp frozen storage

New Jersey Fish Frozen Storage

Rice noddle food processing

Our Turn Key Service

1. Project design

2. Manufacturing

4. Maintenance

3. Installation

1. Project design

2. Manufacturing

3. Installation

4. Maintenance

Video

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

-

skype

Judy

-

Top

BLG.png)