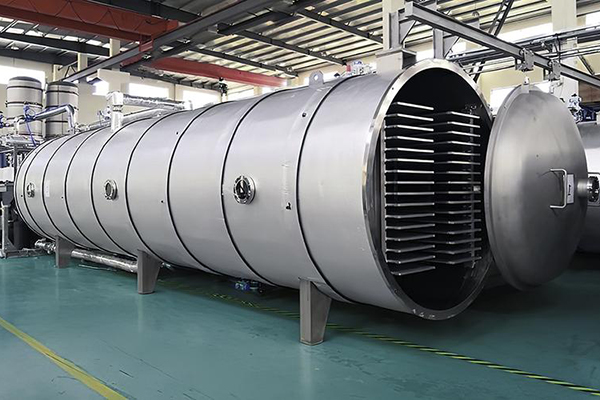

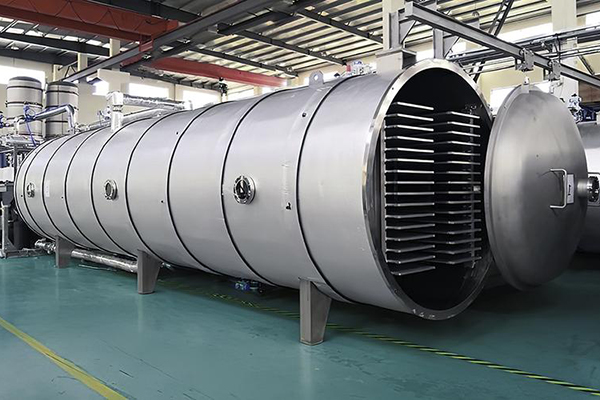

Freeze Dryer

Overview

Features

1. Rail Transport System: U-shaped hangers are used to fix the guide rails, making the material cart lightweight and stable in operation. The guide rails, material carts, and pulley groups are all made of stainless steel and aluminum alloy materials. They are non-corrosive, non-polluting, and have a long service life.

2. The refrigeration unit is an important auxiliary equipment in the FD freeze-drying system. The company matches different manufacturers, models, and types of refrigeration methods according to customer requirements.

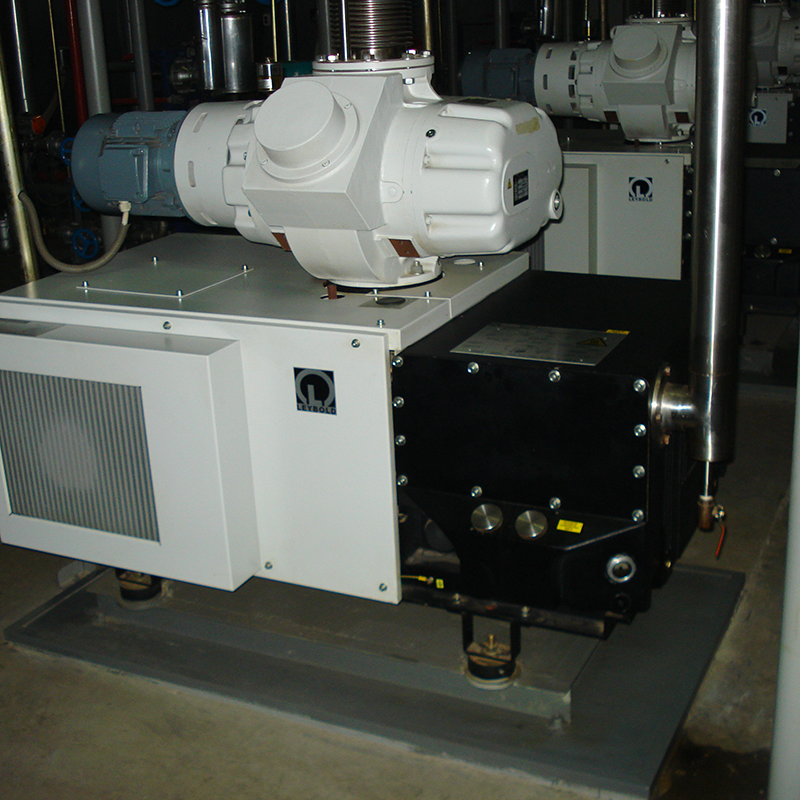

3. The vacuum pump has a small power, high efficiency, low energy consumption, high reliability in production operation, and low cost. Maintenance is simple, and the equipment is clean and hygienic. The vacuum pipeline is made of all stainless steel material, which is aesthetically pleasing and ensures food safety and hygiene.

4. The steam heat exchanger adopts ALFA LAVAL or Kainier brand, which has high efficiency, low energy consumption, small size, module valve array installation, and stable reliability. The thermal medium circulation pump adopts German Wilo or KAIQUAN products, which operate stably and reliably, and has higher operation and maintenance-free. The control regulating device adopts SIEMENS products, which has stable and accurate control and high reliability. The thermal medium adopts distilled water/softened water, with low operating costs, no pollution to products, and can achieve pressurized superheated high-temperature operation.

Parameters

| Items | Freeze Dryer |

| Serial code | FD |

| Cooling capacity | 45 ~ 1850 kW |

| Compressor brand | Bitzer, Hanbell, Fusheng, RefComp and Frascold |

| Evaporating Temp. range | -85 ~ 15 |

| Application fields | Cold storage, Food processing, pharmaceuticals, Chemical industry, distribution center… |

Application

Pet food

Dried yogurt cubes

Fruit tea

Seasonings

Biopharmaceuticals

Vegetable snacks

Our Turn Key Service

1. Project design

2. Manufacturing

4. Maintenance

3. Installation

1. Project design

2. Manufacturing

3. Installation

4. Maintenance

Video

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

-

skype

Judy

-

Top

BLG.png)