Plate freezer

Overview

Features

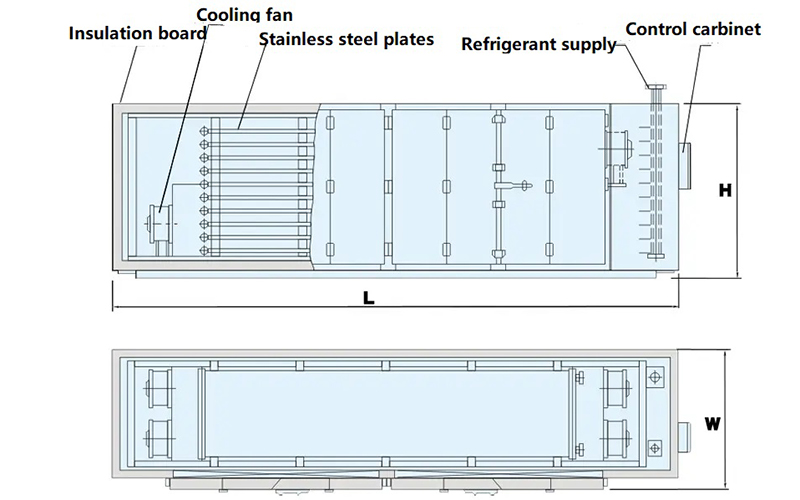

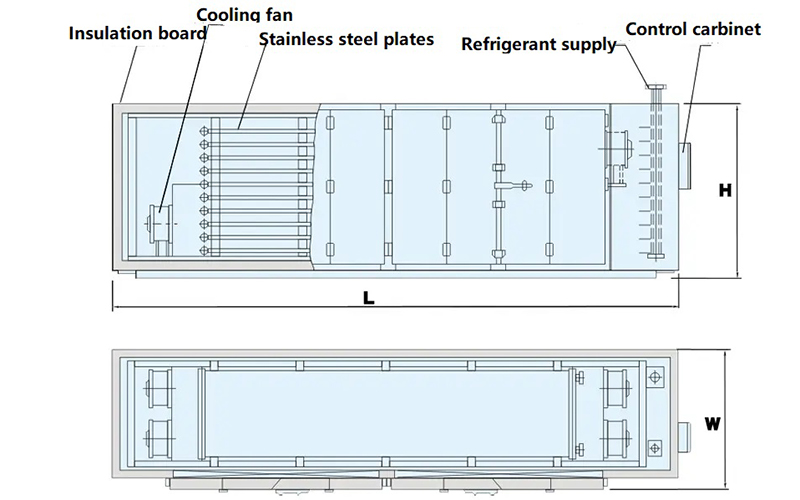

1. All 316L stainless steel material for plate freezer design, safe contact with food. Plate freezers are used to quickly freeze food items by utilizing flat plates that are cooled to low temperatures. The plates come into direct contact with the food items. 316L stainless steel is often used in the construction of plate freezers because it offers several benefits of Corrosion resistance and durability.

2. BOLANG’s unique design for uniform refrigerant liquid distribution ensures efficient freezing of each layer of plates. Uniform refrigerant liquid distribution is the process of evenly distributing refrigerant liquid throughout an evaporator in refrigeration system. The primary purpose of uniform liquid distribution is to ensure that all parts of the evaporator receive the same amount of refrigerant liquid, which is necessary for optimal efficiency and performance of the system. When refrigerant liquid is not evenly distributed in the evaporator, it can cause problems such as poor performance, increased energy consumption, and potential compressor damage.

3. Intelligent control system: The system is responsible for controlling the parameters such as temperature, air flow, and belt speed to maintain optimal conditions for the quick freezing of products passing through the tunnel. The system consists of a human-machine interface (HMI) that allows the operator to view and control the system parameters. The HMI is connected to a Programmable Logic Controller (PLC), which is responsible for monitoring temperature sensors, flow meters, and other sensors that provide data on the system's performance. In case of any abnormality or fault in the system, the control system is equipped with alarms and notifications to alert the operator. The system logs all the critical data points, which helps in diagnosing any problems that might arise during the system's operation.

Parameters

| Items | Plate Freezer |

| Serial code | BL-, BM-() |

| Cooling capacity | 45 ~ 1850 kW |

| Compressor brand | Bitzer, Hanbell, Fusheng, RefComp and Frascold |

| Evaporating Temp. range | -85 ~ 15 |

| Application fields | Cold storage, Food processing, pharmaceuticals, Chemical industry, distribution center… |

Application

Our Turn Key Service

1. Project design

2. Manufacturing

4. Maintenance

3. Installation

1. Project design

2. Manufacturing

3. Installation

4. Maintenance

Video

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

-

skype

Judy

-

Top

BLG.png)

1-300x300.jpg)