Spiral Freezer

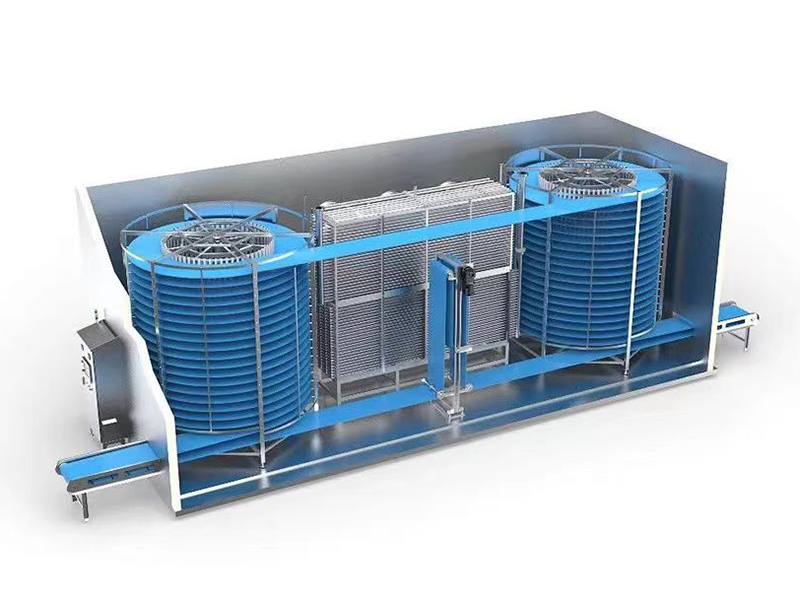

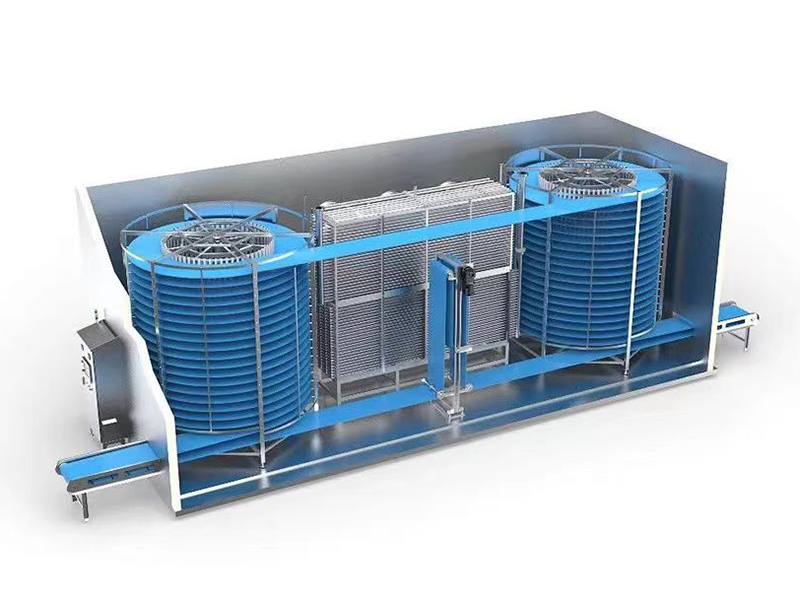

Overview

Features

1. Conveyor belt:Spiral wound on the central drum, used to transfer the product from the freezing machine feed port to the discharge port, all made of 304 stainless steel. It has good turning performance, can achieve 180 degrees of turning, and stable operation, can be shortened and extended to change the spacing of the connection, by lengthening while compressing and then bending laterally, vertical bending is similar to chain drive.

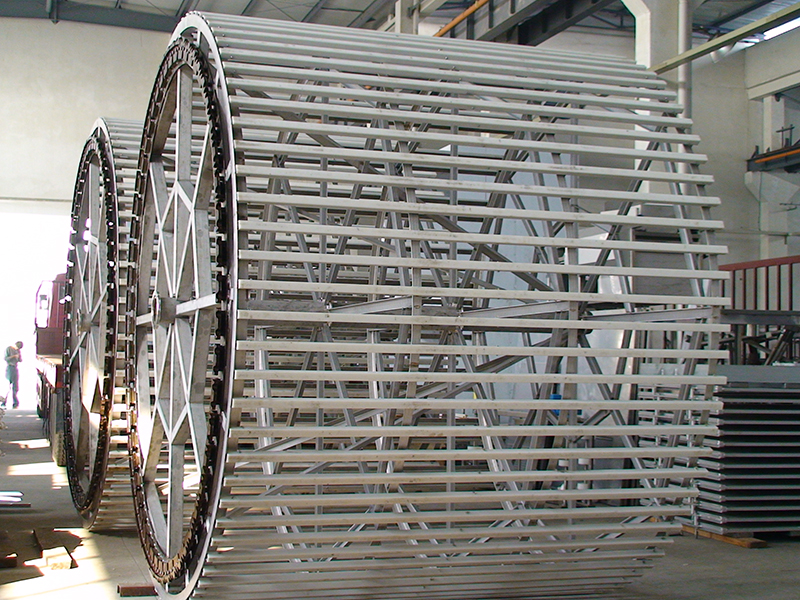

2. Center drum; The center drum is welded by the spindle, ring Angle steel and square steel, the material is 304 stainless steel; such a structure not only effectively strengthens the overall strength, but also plays a role of air conduction, which is conducive to the circulation of cold air and reduces unnecessary cooling consumption. The upper and lower parts of the spindle are supported by bearings. The outer square tube and the direct contact with the net belt parts of ultra high molecular polyethylene material, increase the friction with the conveying net belt, to ensure the service life of the net belt.

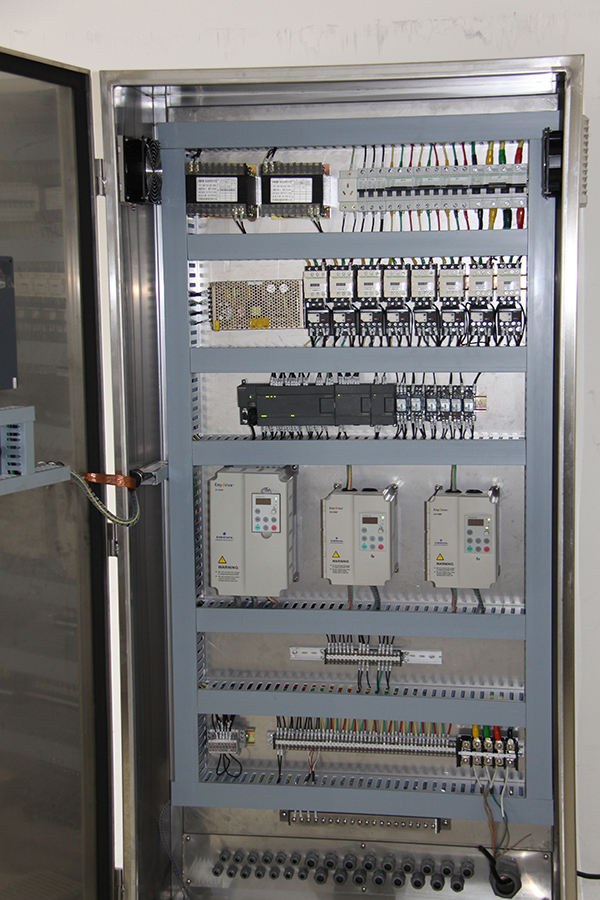

3. Intelligence Control system: The panel of the electrical control cabinet is made of 304 stainless steel and installed outside the thermal insulation wall of the quick-freezing machine. PLC control, touch screen operation, can display the current time, running state, the network through the time (set freezing time), the temperature in the room, the network speed and other current operating parameters. Safety device: with adjusting sensor, conveyor belt upturning sensor, emergency stop switch, frozen product height sensor. If the belt is too loose or the belt is stuck, the belt adjustment sensor will shut down the screw. Two belt tip-up inductors are installed on the first pillar and the opposite pillar. If the conveyor belt is too tight or stuck, the sensor will shut down the spiral freeze machine.

Parameters

| Category | Model | Freezing Ability(Kg/h) | Freeze Time(min) | Machine Cooling Capacity(kw) | Installed Power(kw) | Overall Dimensions(L×W×H) |

| Double spiral freezer | SLD-500 | 500 | 15-75 | 90 | 24 | 10.5×4.3×3.3 |

| SLD-750 | 750 | 15-75 | 135 | 30 | 11.9×4.8×3.3 | |

| SLD-1000 | 1000 | 15-75 | 170 | 32 | 12.8×4.8×3.3 | |

| SLD-1500 | 1500 | 20-100 | 240 | 40 | 12.8×5.5×4 | |

| SLD-2000 | 2000 | 20-100 | 320 | 45 | 14.8×5.6×4.3 | |

| SLD-3000 | 3000 | 25-125 | 460 | 56 | 16.8×6.3×4.3 | |

| Single spiral freezer | DLD-300 | 300 | 15-75 | 55 | 11 | 7.6×4×3.3 |

| DLD-400 | 400 | 15-75 | 70 | 14 | 8.5×4.8×3.3 | |

| DLD-500 | 500 | 15-75 | 85 | 17 | 9.8×4.8×3.3 | |

| DLD-750 | 750 | 15-75 | 135 | 20 | 9.8×4.8×4 | |

| DLD-1000 | 1000 | 20-100 | 170 | 28 | 11.5×5.5×4 |

Note:

- 1.The freezing capacity is based on the reference material of naked frozen South American white shrimp, with a placement density of 4.5kg/m2. The inlet (outlet) temperature is+15 ℃/-18 ℃

- 2.Cooling capacity of the unit: The evaporation temperature/condensation temperature is calculated in (-42 °/+35 ° C).

- 3.The length indicated in the table is the length of the equipment box, excluding the length of the feeding and discharging device. The length of the feeding and discharging device is determined according to the actual requirements of the customer

- 4.The models listed in the above table are for reference only, and the specific plan issued according to customer requirements shall prevail.

Application

Fish

Shrimp

Prepared meal

Dumplings

Rice cake

Seafood

Our Turn Key Service

1. Project design

2. Manufacturing

4. Maintenance

3. Installation

1. Project design

2. Manufacturing

3. Installation

4. Maintenance

Video

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

-

skype

Judy

-

Top

BLG.png)

-300x300.jpg)

1-300x300.jpg)